Ensuring accurate measurement and minimizing lost and unaccounted for (LAUF) gas is essential to ensuring operational efficiency, revenue assurance, and compliance against environmental risks.

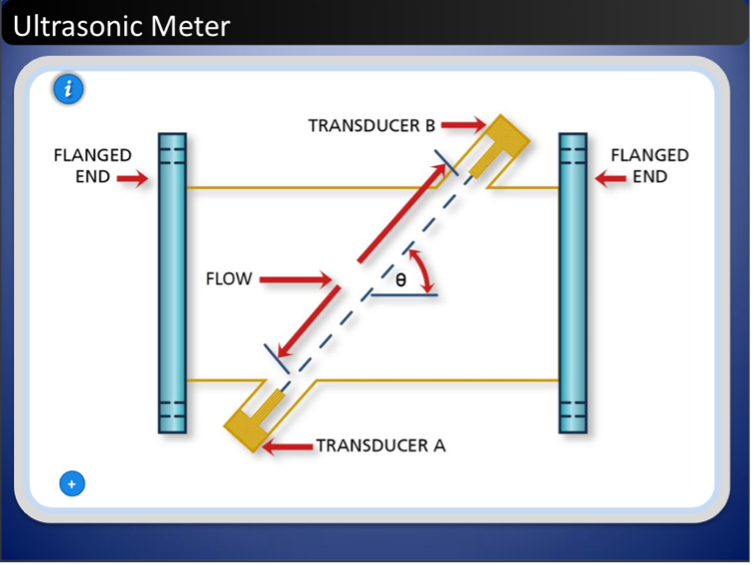

Ultrasonic meters have become a primary device to ensure the reliability and accuracy of gas measurement and are paving the way for minimizing LAUF gas. By providing highly accurate measurement of gas flow rates and volumes, ultrasonic meters improve the overall performance and sustainability of gas transmission.

Enhancing Operational Insight with Ultrasonic Meters

Ultrasonic meters offer significant advantages due to their advanced accuracy and diagnostic capabilities. Within the last few years, the industry has begun to adapt this technology due to the many benefits, including:

- Accuracy of measurement

- Naturally bi-directional, allowing for measurement in both directions

- Lower maintenance due to no moving parts

- Diagnostic feedback that provides insights on the meter’s health and performance

With their improved accuracy and reliability over mechanical meters, ultrasonic meters significantly reduce the risk of over- or under-measuring.

Enhancing Technician Expertise for Meter Operations

Even with the diagnostic feedback and reduced maintenance, it’s important that a technician still understands the theory behind these meters and how to operate and troubleshoot them. As with any new technology, there is a learning curve that must be planned for. While the meters are calibrated at a lab, things can change during transit, affecting the accuracy in the field, which a technician must troubleshoot. As technicians’ knowledge improves on proper operation of the meter, they can troubleshoot when complications arise.

Implementing Courses on Ultrasonic Meters

Continuous education helps to keep up with the learning curve associated with evolving complexities within the industry, with both meters and future changes. Investing in training programs that cover the theory and utilization of meters can greatly improve an organization’s knowledge and efficiency. When developing or investing in curriculum, a core focus should be what technicians need to know to complete their tasks.

“99% of what we do [in measurement] is basic; it’s incredibly important that you know the basics…[we look at] what do these guys need to know to do their job and do their job well.” – Senior Measurement Specialist GTA Member Company

GTA offers up-to-date courses on ultrasonic meters in multiple formats, including web-based (WBT), instructor-led (ILT), and on-the-job training (skill-builders). These courses cover everything from understanding how to read and interpret diagnostics to full installation and troubleshooting of the meter.

Examples of these courses include:

- Ultrasonic Meter Calibration for Gas (WBT)

- Ultrasonic Meter Installation for Gas (WBT)

- Ultrasonic Meter Inspection, Maintenance, and Diagnostics for Gas (WBT)

- Ultrasonic Meters for Gas (ILT)

- Ultrasonic Meter Operation for Gas (skill-builder)

Ultrasonic meters play a pivotal role in achieving accurate gas measurement to mitigate lost revenue and environmental risks. The meters provide reliable and accurate gas measurement, therefore decreasing potential revenue lost from LAUF gas. As the industry continues to advance, ongoing education and training are essential for technicians to effectively maximize the benefits of ultrasonic meters, ensuring continuous improvement in gas measurement practices.

For information on GTA courses available, contact us.